In automated assembly and flexible feeding systems, flexible vibratory bowl feeders are gradually replacing traditional vibratory bowls, becoming essential equipment for handling multi-variety, small-batch production with frequent changeovers. However, during the actual selection process, many users encounter similar questions:

How to choose the right flexible vibratory bowl feeder?

Why do prices vary so much between different brands and solutions?

Where does the value of high-priced solutions lie, and are they truly worth the investment?

I. Selection Logic for Flexible Vibratory Bowl Feeders

Reasonable selection is the prerequisite for stable feeding and long-term operation. Key aspects to focus on include:

1. Material Size and Weight

The size range and unit weight of materials directly determine the specifications of the vibratory bowl surface and driving capacity. For heavier metal parts or larger workpieces, it is necessary to select a bowl model with greater load-bearing capacity to avoid issues such as overload operation, insufficient vibration, or reduced lifespan.

2. Material Shape and Orientation Requirements

The geometric complexity of materials is one of the key factors affecting the selection of flexible vibratory bowl feeders. For irregular parts, asymmetric parts, or workpieces with strict orientation requirements, custom-designed bowl structures or optimized vibration strategies are often needed to improve the success rate and stability of materials being vibrated into the correct orientation.

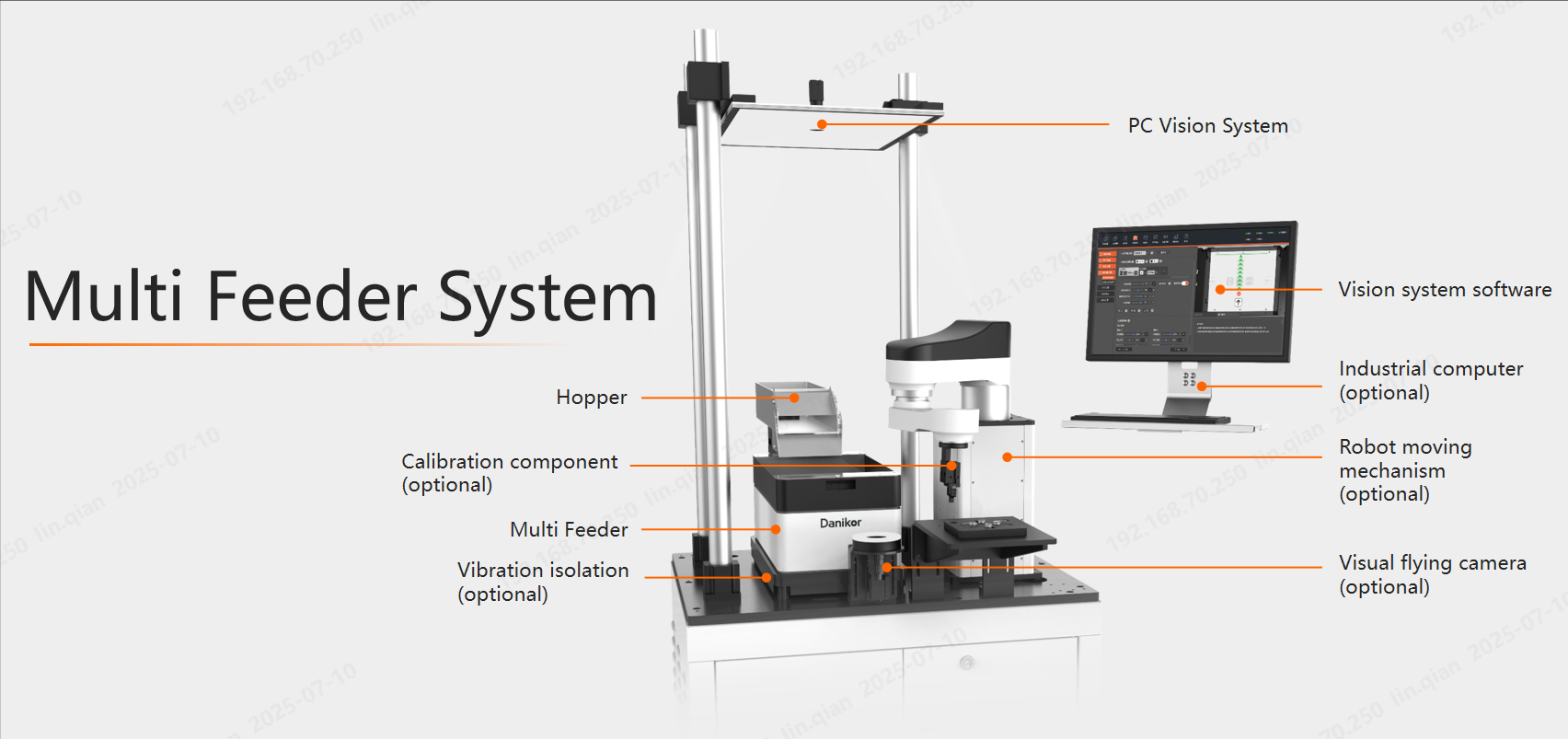

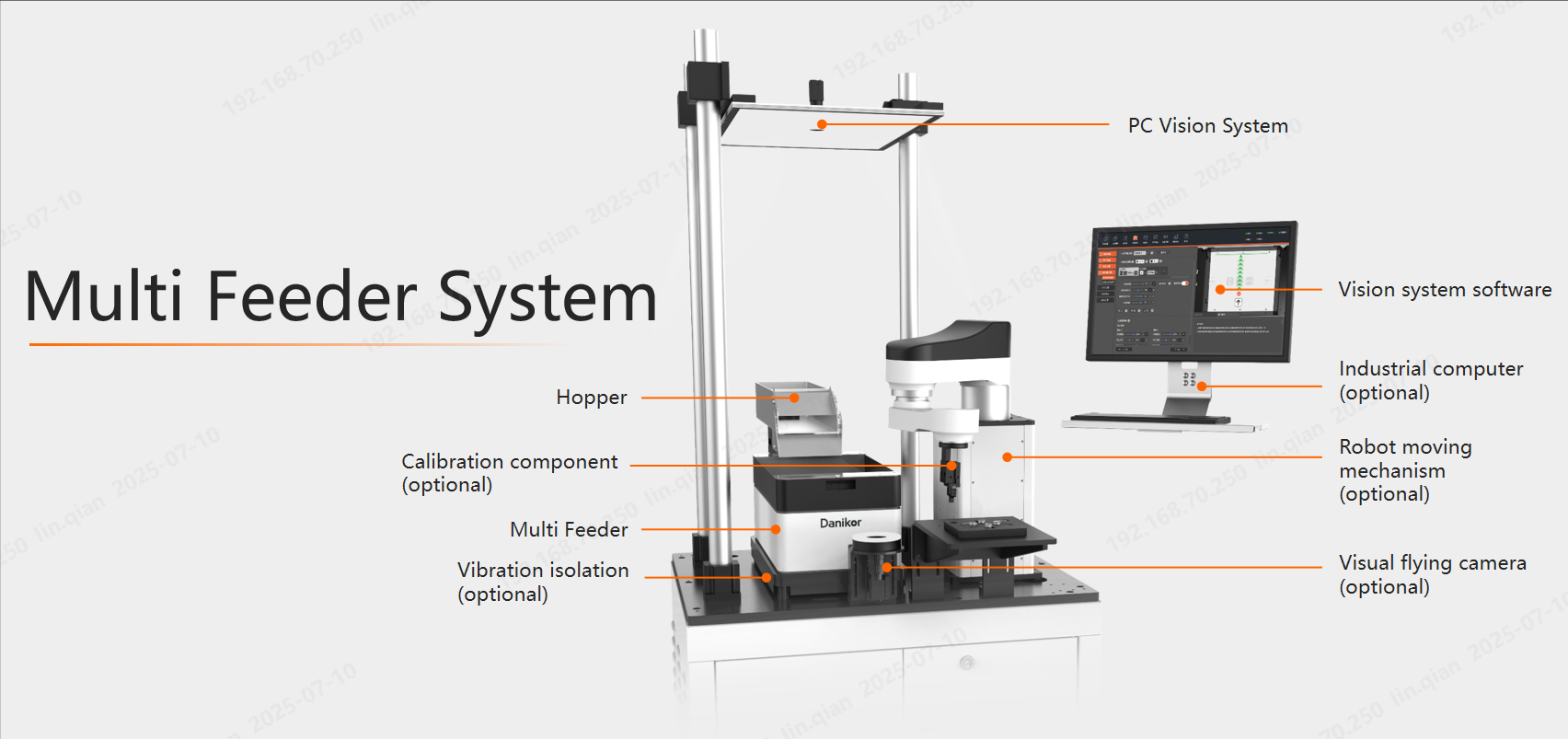

3. Cycle Time and System Compatibility

Flexible vibratory bowl feeders typically need to work in coordination with industrial robots, vision systems, and assembly stations. Therefore, their discharge cycle time, positioning accuracy, and communication interfaces must match the overall line cycle to avoid becoming a production bottleneck due to unstable feeding.

4. Supplier's Technical and Service Capabilities

Selection is not just about choosing equipment, but also about choosing a partner. Suppliers with mature application experience can conduct incoming material testing and solution validation during the pre-sales phase, assessing feasibility in advance and significantly reducing later debugging risks.

II. Cost Structure of Flexible Vibratory Bowl Feeders: Where Do Price Differences Come From?

The price range of flexible vibratory bowl feeders on the market varies significantly, which often reflects differences in cost structure and technical approaches, mainly manifested in the following aspects:

1. Core Component Costs

The drive unit is the core of the flexible vibratory bowl feeder. The performance and quality of voice coil motors directly affect vibration response speed, stability, and service life. Although high-quality core components cost more, they offer obvious advantages in reliability and consistency during long-term operation.

2. Production Processes and Technical Barriers

Solutions that adopt precision machining equipment, self-developed control algorithms, and in-house manufacturing of core components have advantages in consistency and system stability. However, their manufacturing costs are significantly higher than products that simply purchase standard components for assembly. At the same time, technical R&D such as vibration control strategies and vision adaptation capabilities also constitute important hidden costs.

3. Functional Configuration and Expansion Capabilities

Whether it supports quick switching between multiple materials, compatibility with different bowl specifications, and deep integration with multi-brand robots and vision systems will all impact the overall price. The richer the functions and the stronger the scalability, the higher the corresponding system cost.

4. Service and Delivery Models

Models that only provide hardware sales have relatively lower initial prices. Complete solutions that include preliminary process evaluation, technical training, on-site commissioning, and post-maintenance support are usually priced higher but can significantly reduce the customer's usage threshold and operational risks.

Danikor provides free incoming material testing and customized solutions during the pre-sales phase, verifying in advance the applicability of the flexible vibratory bowl feeder to actual materials. During the after-sales phase, we provide rapid response and technical support to help customers maintain stable operation. Although such services increase initial costs, from the perspective of overall input-output ratio, they often offer better cost-effectiveness.

Conclusion

The purchase of flexible vibratory bowl feeders should not focus solely on "price levels" but should be comprehensively evaluated from three dimensions: application matching, cost structure, and long-term value. A reasonable selection solution can not only improve current production line efficiency but also reserve space for future product iterations and production line upgrades.

For enterprises pursuing stability, flexibility, and sustainable production, choosing a flexible vibratory bowl feeder solution with mature technology and a comprehensive service system is often a more valuable long-term investment.