From the Perspective of Flexible Feeder Manufacturers: The Inevitability of Voice Coil Motors as Mainstream

In the field of industrial automated feeding, flexible vibratory bowl feeders are being used increasingly widely, and the choice of power source directly determines their operational accuracy and adaptability. Many companies consulting with flexible vibratory bowl feeder manufacturers ask: why are more and more manufacturers now adopting voice coil motors as the core power source? As a manufacturer with years of experience in the industry, Danikor combines its own R&D and production experience to analyze this industry trend in detail through a series of Q&As, while also introducing the core advantages of flexible vibratory bowl feeder manufacturers.

Q&A 1: Flexible vibratory bowl feeders have multiple power source options—why have voice coil motors become mainstream?

This is the core question many companies ask when consulting flexible vibratory bowl feeder manufacturers. The answer mainly lies in the adaptability and practicality of voice coil motors. The drive system is the core component of a flexible vibratory bowl feeder. Traditional vibratory bowls mostly rely on electromagnetic drives, which can only achieve single-trajectory vibration. When handling complex materials such as tiny, irregularly shaped, or fragile items, they easily cause material jamming or damage, failing to meet the diverse needs of modern manufacturing.

In contrast, voice coil motors can flexibly adjust vibration frequency and amplitude to achieve various motion effects such as material dispersion, flipping, and orientation. They can adapt to feeding requirements for different specifications and materials, aligning with the "multi-variety, small-batch, high-precision" production characteristics of modern manufacturing. Furthermore, with technological upgrades, voice coil motors can now achieve one-button frequency finding, significantly shortening equipment debugging time and improving changeover efficiency—key reasons why flexible vibratory bowl feeder manufacturers prioritize them.

.png)

Q&A 2: How do flexible vibratory bowl feeder manufacturers optimize the application effects of voice coil motors?

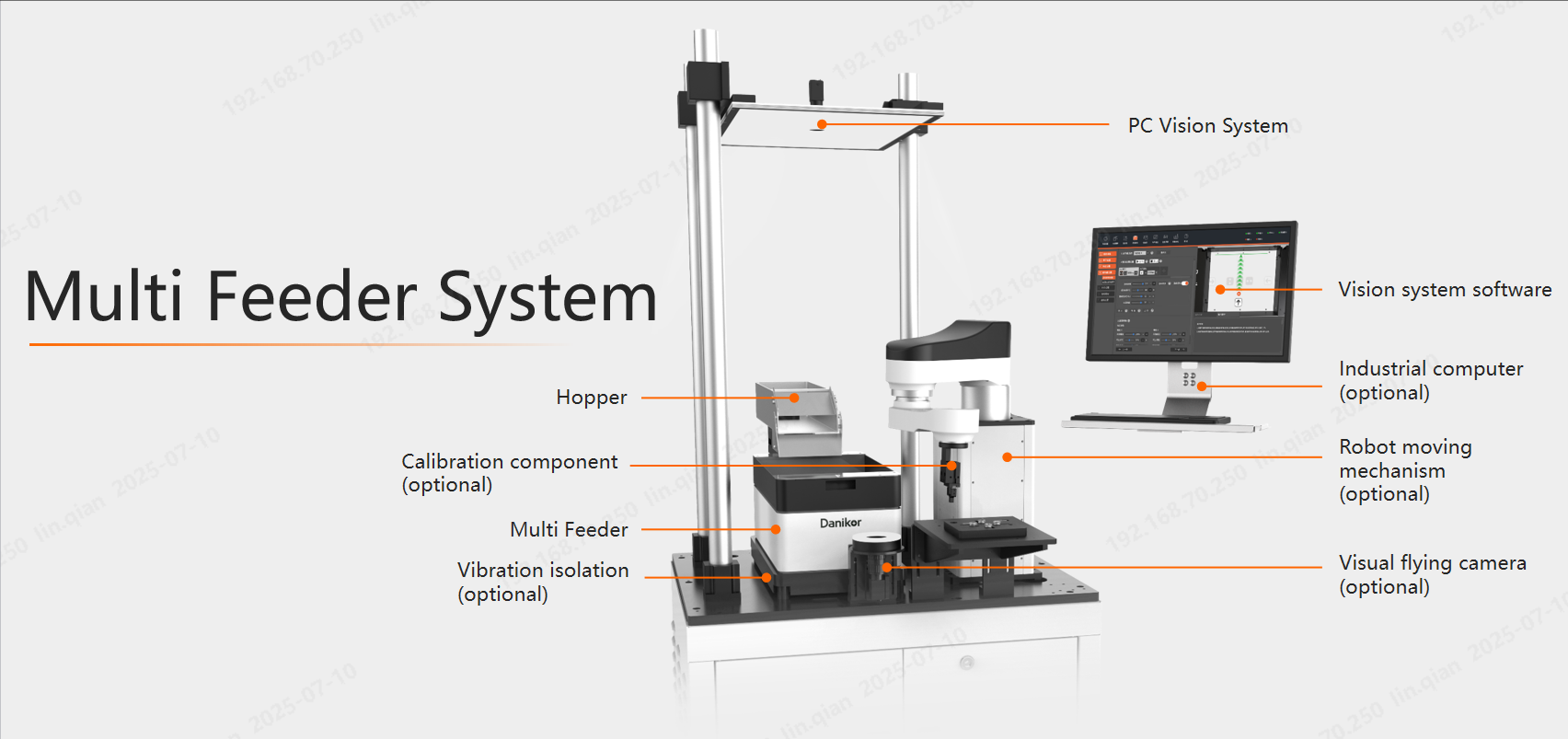

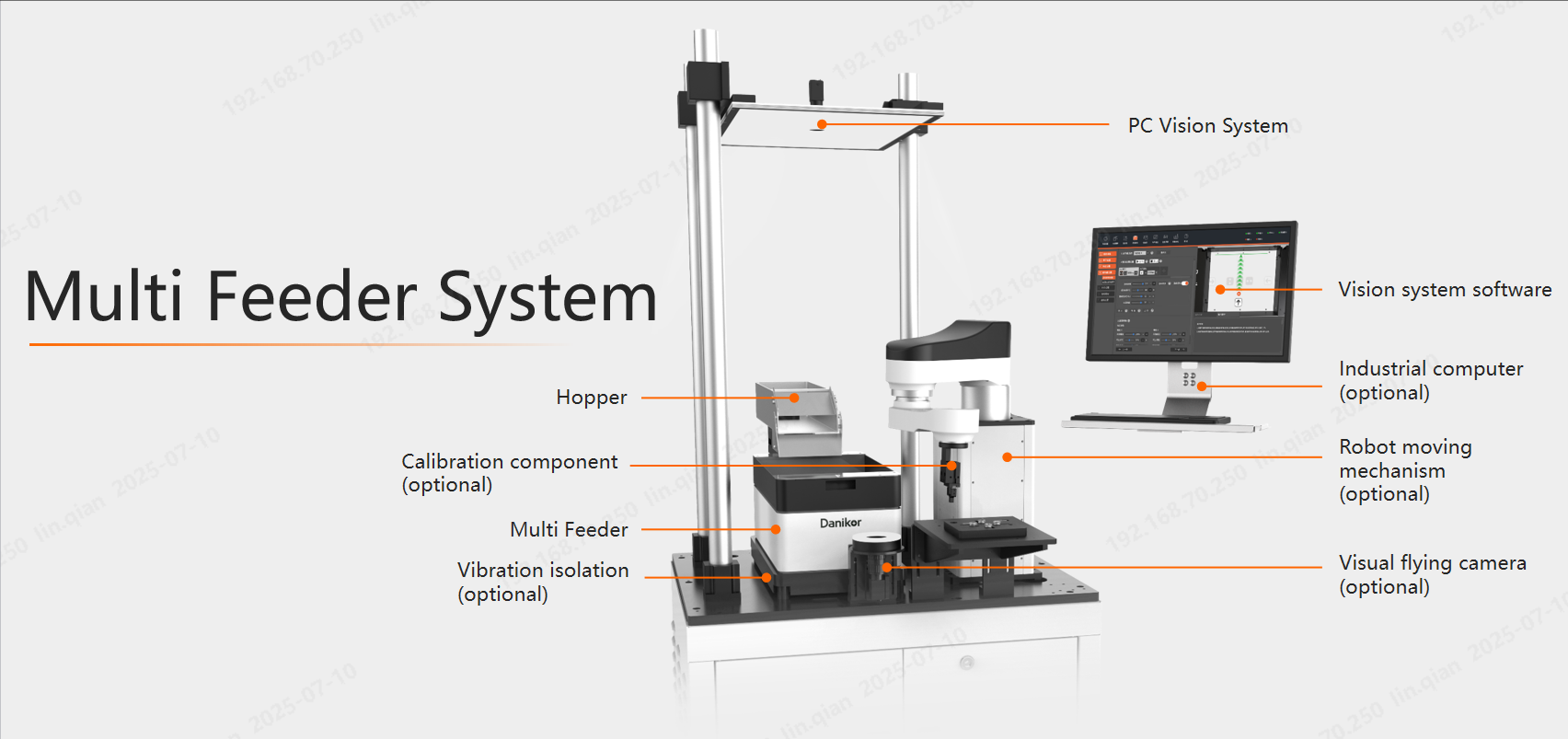

Not all flexible vibratory bowl feeder manufacturers can leverage the core advantages of voice coil motors. Professional manufacturers optimize through technology to achieve the expected compatibility between the two, with Danikor being a representative example. As a manufacturer focused on R&D and production of flexible vibratory bowl feeders, Danikor has been deeply involved in the industry for over ten years, possessing a complete R&D and production system. Its flexible vibratory bowl feeders are all equipped with customized voice coil motors, achieving complementary performance through debugging.

As a flexible vibratory bowl feeder manufacturer, Danikor optimizes voice coil motor power and control logic according to material characteristics in different industries. For example, for precision electronic components, motor amplitude is adjusted to micrometer levels to avoid material scratching; for irregular hardware parts, vibration frequency is optimized to ensure stable directional conveying. This customized service is also the core competitiveness that distinguishes professional flexible vibratory bowl feeder manufacturers from ordinary ones.

Q&A 3: What industry pain points can voice coil motors paired with flexible vibratory bowl feeders solve?

This is also a key topic when flexible vibratory bowl feeder manufacturers communicate with companies. Pain points of traditional feeding equipment mainly concentrate on material jamming, slow changeover, material damage, and cumbersome debugging. Voice coil motor-driven flexible vibratory bowl feeders can specifically address these issues. Practical application cases from flexible vibratory bowl feeder manufacturer Danikor show that flexible vibratory bowl feeders equipped with voice coil motors have a jamming rate far below the industry average, with material damage rates reduced by over 90%.

Meanwhile, the one-button frequency finding function significantly shortens equipment changeover time from several hours traditionally to just a few minutes, greatly improving production line utilization and adapting to multi-variety mixed-line production needs. Whether in high-precision industries such as electronics, automotive, and medical devices, or conventional industries such as hardware and plastics, this combination performs stably—an important reason why flexible vibratory bowl feeder manufacturers vigorously promote voice coil motor power sources.

Q&A 4: When selecting a flexible vibratory bowl feeder manufacturer, why prioritize voice coil motor configuration?

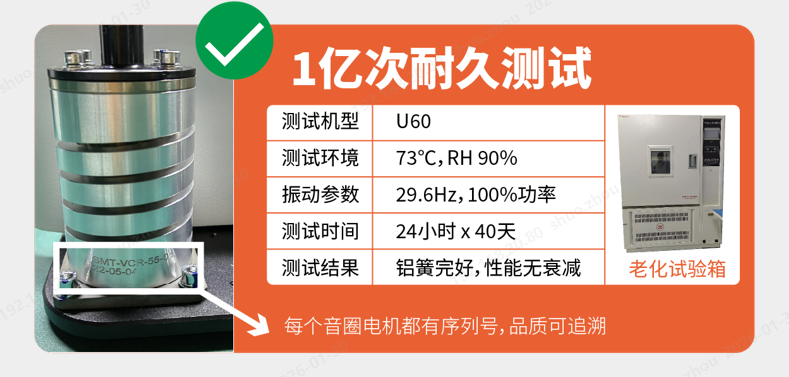

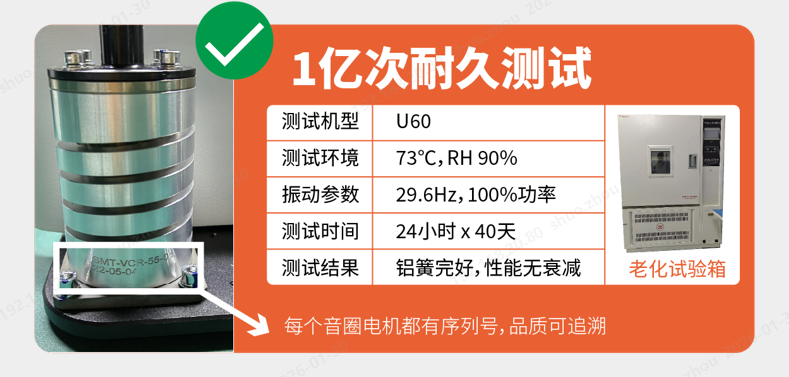

As industrial automation levels improve, companies have increasingly higher requirements for the precision, efficiency, and adaptability of flexible vibratory bowl feeders, and voice coil motor configuration directly determines the core performance of the equipment. Flexible vibratory bowl feeder manufacturers like Danikor not only select high-quality voice coil motors but also pair them with self-developed control systems to achieve seamless coordination between the motor and vibratory bowl, ensuring long-term stable operation.

For companies, choosing flexible vibratory bowl feeders equipped with voice coil motors can reduce subsequent equipment maintenance costs, improve production efficiency, and adapt to more diverse production needs. Therefore, when consulting with flexible vibratory bowl feeder manufacturers, paying attention to voice coil motor configuration and optimization technology is key to selecting equipment.

Voice coil motors becoming the mainstream power source for flexible vibratory bowl feeders is the inevitable result of industry technological upgrading, and also inseparable from the continuous R&D and promotion by flexible vibratory bowl feeder manufacturers. As a reliable flexible vibratory bowl feeder manufacturer, Danikor always takes corporate needs as the core, creating high-precision, high-adaptability, and high-efficiency flexible vibratory bowl feeders through optimized voice coil motor application technology, providing professional automated feeding solutions for various industries and helping companies achieve production line upgrades.

.png)