How Flexible Feeding Uses AI to Distinguish Parts with Minimal Visual Differences

In the field of intelligent manufacturing, flexible feeding technology is gradually becoming a key driver of production efficiency and quality.

However, real-world applications often involve parts whose front and back surfaces differ only by tiny details. Traditional vision systems struggle to distinguish them, leading to mis-picks, lower throughput and material waste.

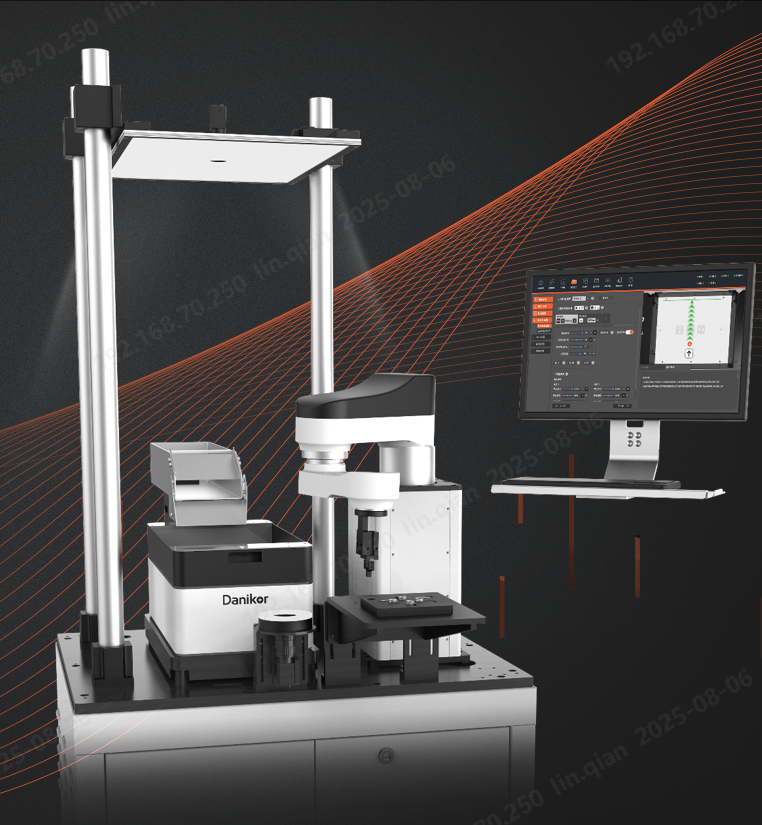

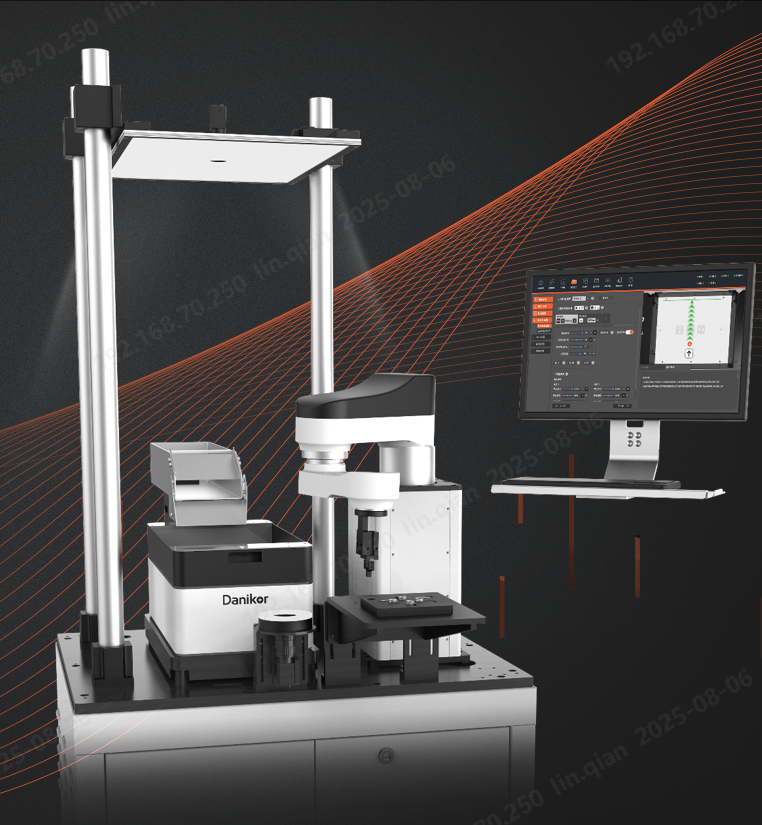

To solve this pain-point, Danikor’s flexible vibratory bowl feeder introduces an AI-powered algorithm that makes reliable differentiation possible.

Core Advantage – AI Visual Intelligence

Conventional vision solutions rely on manually selected feature points. This is time-consuming, operator-dependent and delivers unstable accuracy.

Danikor’s system instead uses AI to autonomously learn the appearance of each side of a part under every possible position and angle, building a high-precision recognition model.

Workflow in Three Simple Steps

Create Sample Libraries

Two folders are created: “Side A” and “Side B”. The operator simply collects a small batch of images for each side and saves them into the corresponding folder.

One-Click Training

Deep-learning algorithms automatically extract distinguishing features and train a dedicated model. No programming or vision expertise is required.

Run & Feed

During production the camera captures each part on the vibrating surface in real time. The AI instantly decides which side is facing up and guides a robot or pick-and-place unit to collect only parts in the desired attitude.

Human intervention is minimized while feeding accuracy and speed are greatly increased.

Adaptability & Scalability

When part geometry, size or surface texture changes, the operator only needs to add new images and retrain the model. Within minutes the system is ready for the new component.

This flexibility makes the Danikor AI bowl feeder suitable for electronics, automotive, medical devices and many other industries.

Conclusion

By embedding AI visual intelligence into flexible feeding, Danikor eliminates the long-standing difficulty of distinguishing parts with almost identical front and back surfaces. The result is higher yield, lower scrap and a solid step toward fully intelligent production.

In the era of smart manufacturing, Danikor’s AI-driven flexible vibratory bowl continues to help companies achieve faster, more accurate and more adaptable feeding solutions.