How to Choose Between Blow Feeding and Vacuum Suction Modules in Automatic Screw Driving?

In automatic screw driving systems, the feeding method directly affects tightening stability, cycle time, and workstation adaptability. Currently, mainstream solutions mainly include two forms: blow feeding and vacuum suction feeding. These two differ significantly in structural principles, screw support methods, and spatial adaptability, so reasonable selection must be made according to specific working conditions.

I. What are the common tightening interference conditions in automatic screw driving?

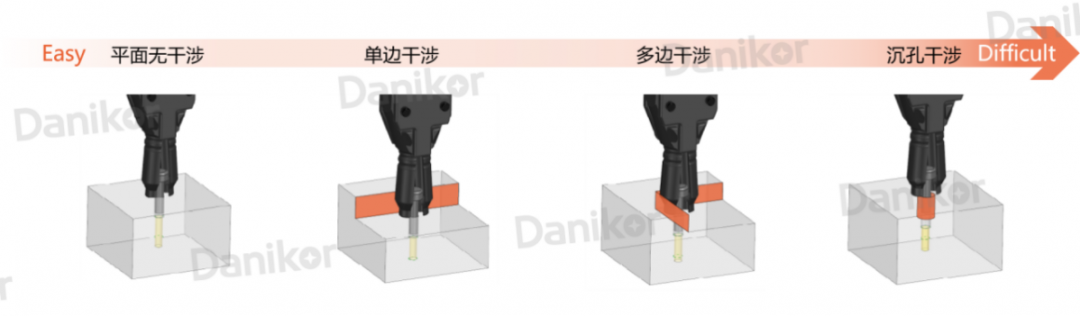

In automated assembly lines, according to the complexity of the spatial structure around the tightening hole position, common interference conditions can be divided into four categories:

• Planar Non-Interference: No obstructions around the hole position, lowest tightening difficulty

• Single-Side Interference: Vertical walls or structures exist on one side of the hole position, requiring evaluation of the screwdriver head opening direction

• Multi-Side Interference: Interference exists in multiple directions, requiring higher standards for screw feeding and hole entry paths

• Countersunk Hole Interference: The tightening point is below the product surface, with small hole depth and edge distance, highest tightening difficulty

As the degree of interference increases, the difficulty of selecting tightening modules also rises accordingly.

Facing different tightening interference conditions, different types of tightening module solutions need to be adopted to ensure that when performing tightening, the screwdriver head drives the screw to enter the hole smoothly without obstruction. Usually, there are two forms of modules—blow feeding and suction feeding—to eliminate interference effects and ensure successful tightening. So under different interference conditions, what rules are used to choose between blow feeding or suction feeding forms?

II. What is a blow feeding module? What is its working principle?

A blow feeding module is an automatic screw feeding and tightening solution that transports screws to the screwdriver head through airflow. Its typical workflow includes:

Screws are blown to the screwdriver head through airflow

The screwdriver head clamping jaws support the screw and expose a certain length

The module moves to the tightening hole position

The clamping jaws open and execute the tightening action

This method has a simple structure and fast action cycle, making it a common solution in automatic screw driving.

III. Which interference conditions are suitable for selecting blow feeding modules?

When the following conditions are met, blow feeding modules are priority recommendations:

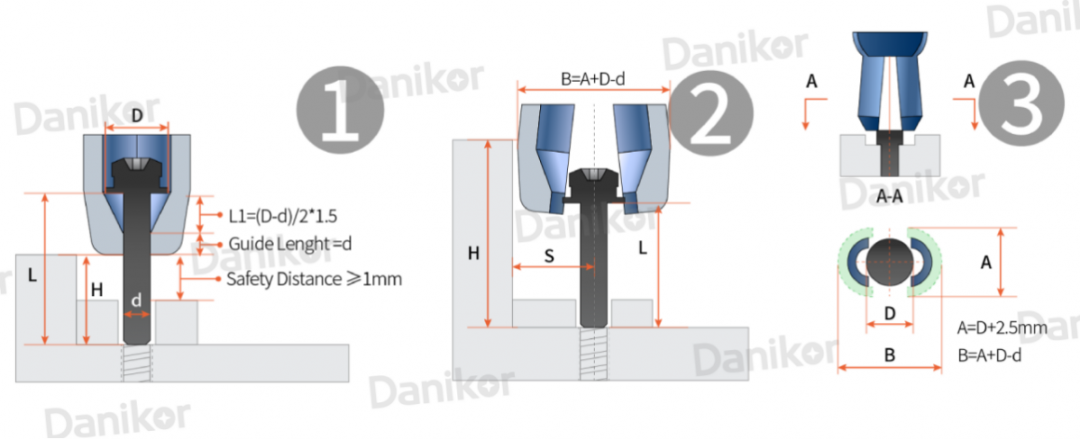

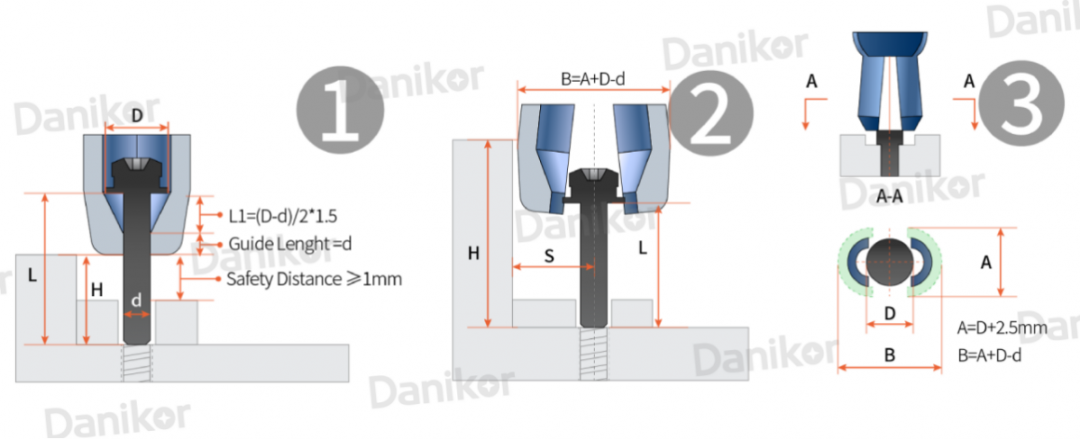

Image showing three scenarios with dimensional parameters:

① When L-L1-d-2 > H, select blow feeding form;

② When L-L1-d-2 < H, and S > B/2, blow feeding form is optional;

③ If the A-A direction doesn't work, rotate the screwdriver head 90°, and when S > A/2, blow feeding form is optional;

• Suitable for Planar Non-Interference or Single-Side Interference tightening conditions

• For single-side interference, both left-right and front-back directions meet screwdriver head movement space requirements

• After the screw is supported by the clamping jaws, it exposes a certain length and is allowed to pass through the tightening hole by approximately 2mm

• The clamping jaw opening direction will not collide with workpiece structure

IV. What is a vacuum suction module? What is the difference from blow feeding modules?

Vacuum suction modules introduce a vacuum adsorption structure based on blow feeding. Its core characteristics are:

• After the screw is clamped at the screwdriver head

• The screw is picked up through the suction tube using vacuum adsorption

• The suction tube sends the screw into the tightening hole position

• Then completes the tightening action

Compared to blow feeding modules, vacuum suction modules have stronger adaptability under complex interference conditions.

V. Which interference conditions are suitable for selecting vacuum suction modules?

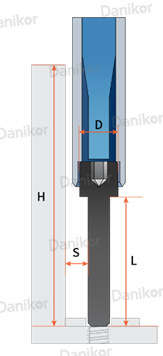

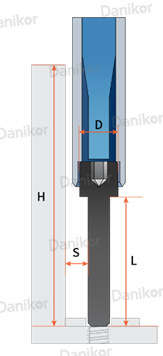

Image showing dimensional parameters for suction module

• When S > D/2+2, the suction form can be selected

• When the screw length-to-diameter ratio is favorable for blowing, use blow-plus-suction module

• When the screw length-to-diameter ratio is too small and unsuitable for blowing, use pick-and-place module

Facing different installation spaces and interference conditions, selecting the appropriate tightening module is the core prerequisite for ensuring assembly efficiency and tightening quality.