I. Why is Bolt Tightening Consistency So Important?

In the fields of automotive manufacturing, 3C products, construction machinery, and new energy equipment assembly, bolt tightening consistency directly determines the structural strength, service life, and safety of products. However, in actual production processes, issues such as tightening inconsistency, torque fluctuation, missed tightening, or over-tightening still occur frequently, becoming important factors affecting assembly quality and yield rate.

II. What Are the Main Causes of Bolt Tightening Inconsistency?

In actual assembly, the factors affecting bolt tightening consistency mainly include the following aspects:

Insufficient Tool Precision

Traditional clutch-type torque tools inherently have large dispersion. With increased usage time, spring fatigue and mechanical wear will lead to output torque deviation, making it difficult to guarantee long-term consistency.

Human Operation Differences

Handheld tightening relies on manual experience. Differences in pressing force, angle, and rhythm among different operators will directly affect tightening results.

Thread and Working Condition Differences

Different bolt surface treatments, lubrication states, and connector rigidity will all cause clamping force differences under the same set torque.

Unreasonable Tightening Strategy

In hard connections or high-speed tightening scenarios, if the final tightening stage is not properly controlled, torque overshoot is easily generated, destroying tightening consistency.

III. How to Fundamentally Improve Bolt Tightening Consistency?

Adopt Intelligent Tightening Tools to Achieve Closed-Loop Control

The servo electric tightening gun is the key equipment for improving tightening consistency. Compared with traditional tools, intelligent tightening guns have the following advantages:

Built-in torque sensor and angle encoder

Real-time monitoring of torque, angle, and rotation speed

Dynamic adjustment of motor output through closed-loop control

Stop after reaching the target tightening value to avoid overshoot

Through data feedback, every tightening operation strictly executes the same process parameters, ensuring consistency from the source.

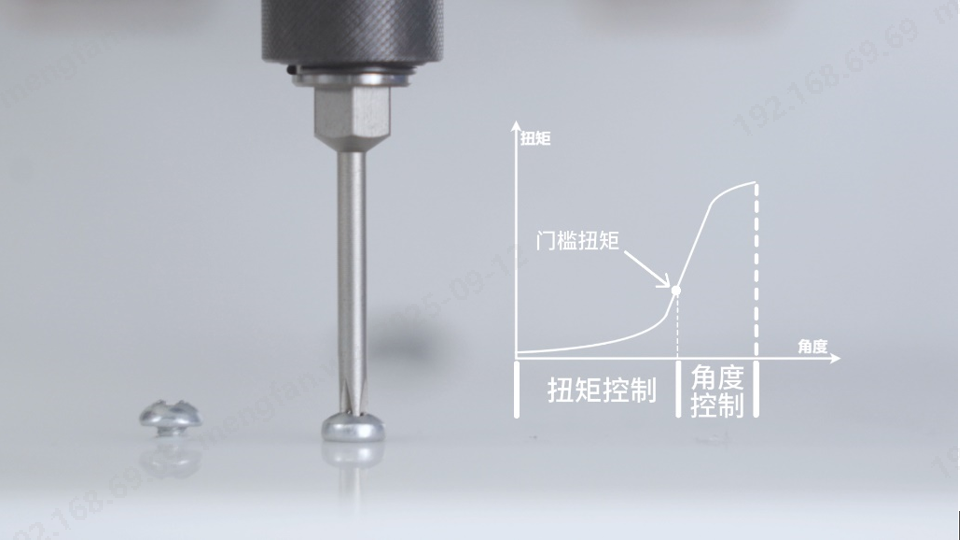

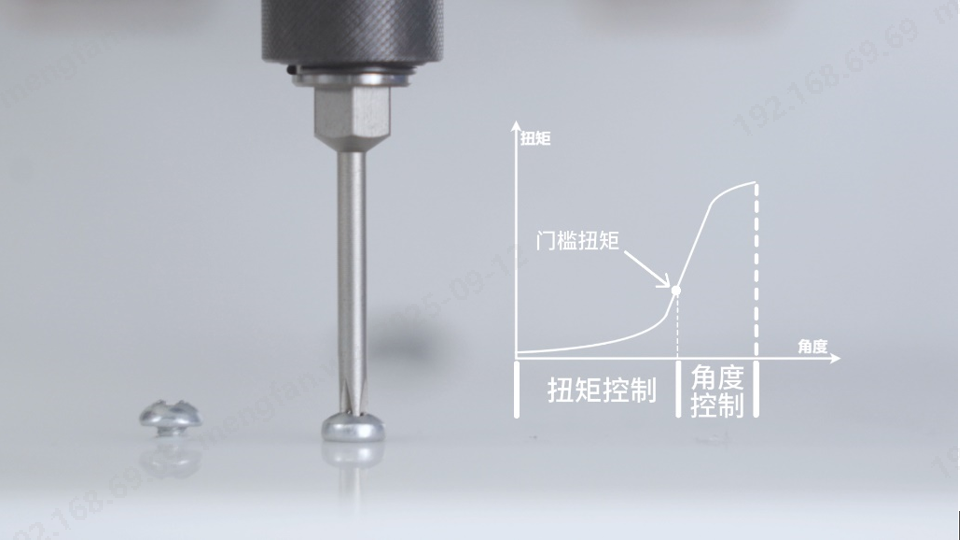

Reasonably Select Tightening Strategy to Improve Process Stability

Different working conditions should be matched with different tightening strategies, for example:

Torque Control: This is the most basic control method, where tightening stops immediately when the preset target torque value is reached. It is mainly applicable to non-critical connections, batch production with low precision requirements, and scenarios where bolt strength is high and friction coefficient is stable (such as home appliances and general machinery).

Angle Control: Angle control continues rotation for a preset angle after reaching the starting torque before stopping. It is mainly applicable to tightening in the plastic deformation zone, occasions requiring high tightening force consistency, and connections with good bolt material ductility.

Torque Plus Angle Control: This is a staged control method, first reaching the starting torque, then rotating a specified angle (e.g., 20Nm + 90°). It is mainly applicable to critical connections (such as engine cylinder heads, wind turbine flanges, rail transportation), and occasions requiring utilization of bolt plastic deformation to achieve high-precision assembly.

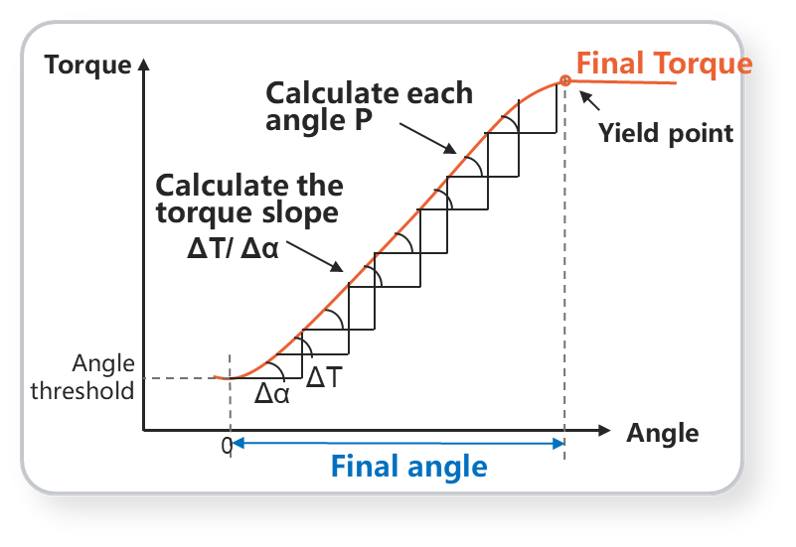

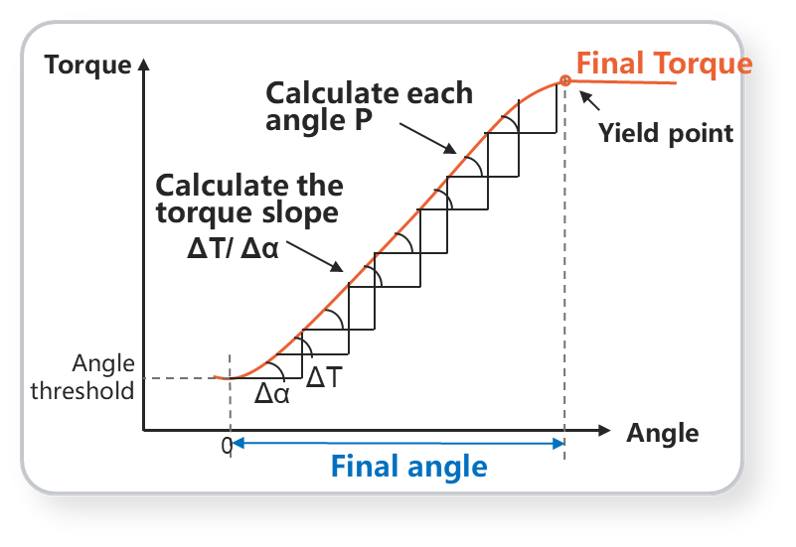

Yield Point Control: This method identifies the material yield point (curve inflection point) through the torque-angle curve and stops tightening immediately. It is mainly applicable to precision assembly of nuclear power equipment sealing connections, aero-engines, and critical bolts in automotive final assembly. It is not affected by the friction coefficient of the torque method or the starting point of the angle method of the angle method, and has high tightening precision with material utilization up to 100%. However, it has high requirements for working conditions, and consistency of bolts and quality of mating surfaces must be ensured.

Reasonable strategy settings can effectively reduce the impact of working condition changes on tightening results.

Tightening Data Collection and Traceability to Achieve Process Control

High consistency cannot be achieved without data support. Tightening tools used in conjunction with controllers can achieve:

Visualization of relevant data such as torque, angle, and duration of each screw, generating tightening curves;

Monitoring of torque or angle at every stage from cap recognition, thread recognition, screwing, seating to final tightening, with timely NG prompts when tightening abnormalities occur.

Data management not only improves consistency but also provides a basis for quality improvement.

Through systematic solutions, enterprises can obtain multiple benefits:

Improved product assembly reliability and safety

Reduced rework rate and quality risks

Stable production rhythm and improved production line efficiency

Bolt tightening consistency is not a problem that can be solved by a single device or parameter alone, but rather the result of the synergistic effect of tool selection, tightening strategy, automation level, and data management.