In the fields of automotive manufacturing, aerospace, and precision electronic equipment assembly, the quality of the fastening process directly determines the safety and durability of the product. As the "star" tool on the assembly line, the electric torque screwdriver has long replaced traditional pneumatic tools and become the standard for high-precision fastening. So how exactly does an electric torque screwdriver ensure that every bolt can accurately meet the preset requirements? This article will deeply analyze how electric torque screwdrivers utilize these two core components to achieve closed-loop control of torque and angle.

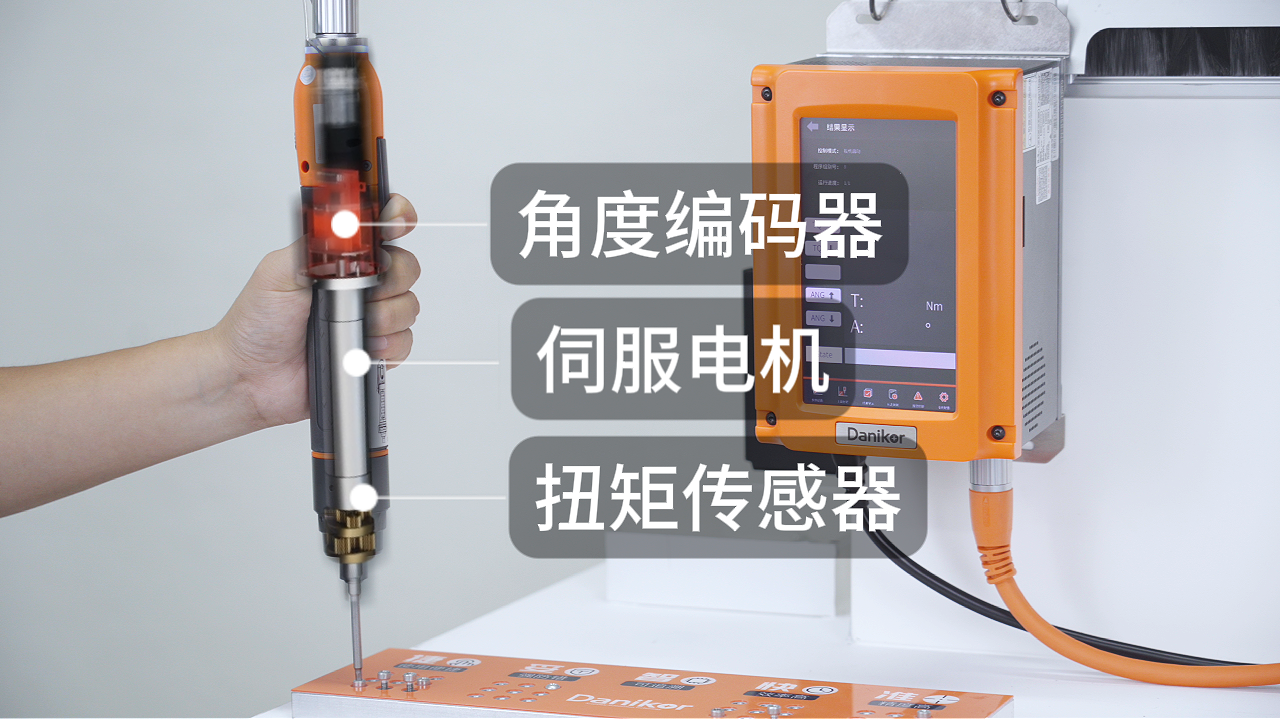

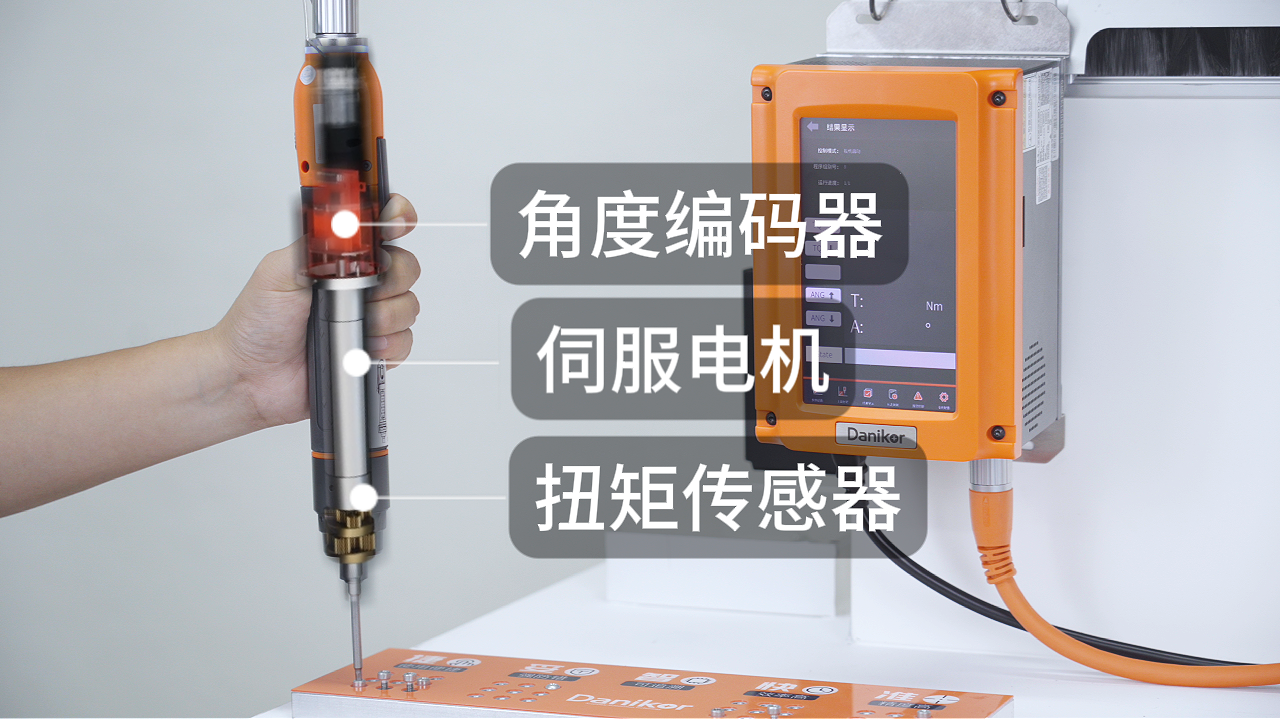

Early fastening tools relied on clutch disengagement or the operator's experience to make judgments, a method that was greatly influenced by the environment, friction, and human factors. The essence of a modern electric torque screwdriver is a miniaturized electromechanical integrated system that combines a servo motor, precision reduction mechanism, and intelligent sensing system.

An electric torque screwdriver has only two core tasks:

How much force to output? (Torque control)

How many turns to tighten? (Angle control)

To accomplish these two tasks, the electric torque screwdriver internally constructs a complex real-time feedback system, which relies on the close cooperation of two core "sensors": the torque sensor and the angle encoder.

I. Torque Sensor: The "Sense of Touch" of the Electric Torque screwdriver

Torque is the most intuitive indicator for evaluating fastening quality. Electric torque screwdrivers typically use dynamic torque sensors to obtain data in real-time.

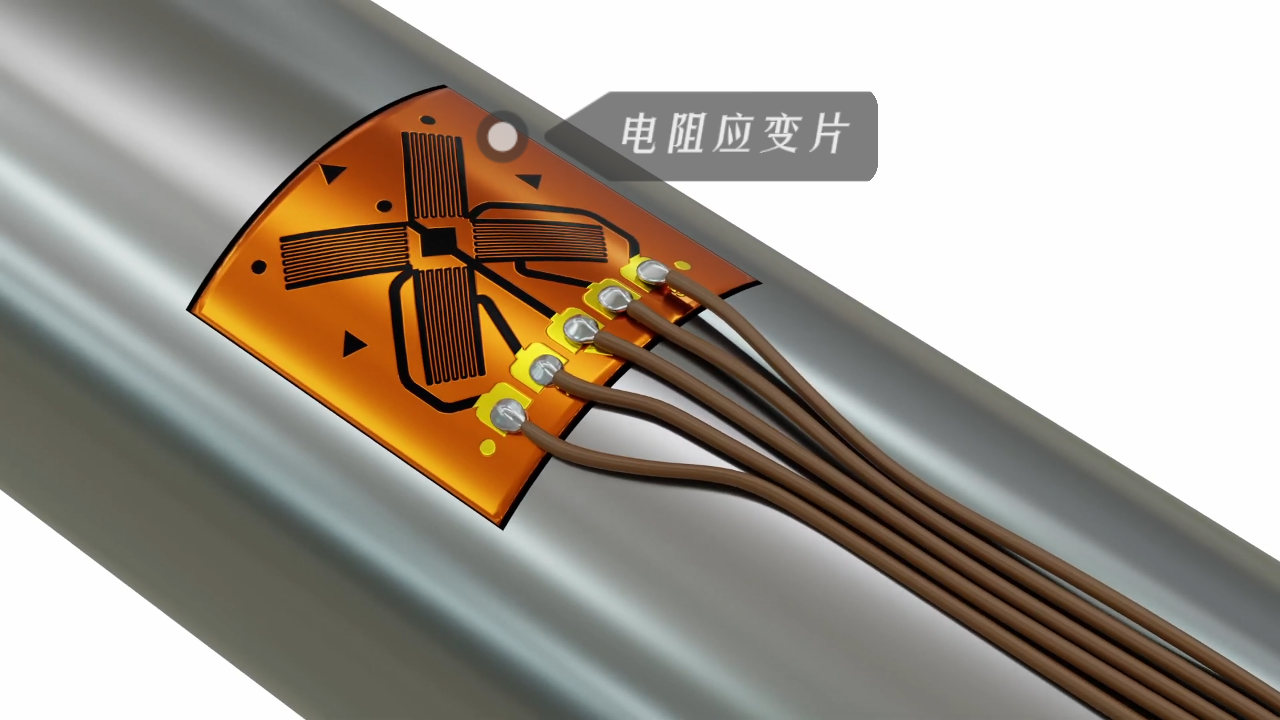

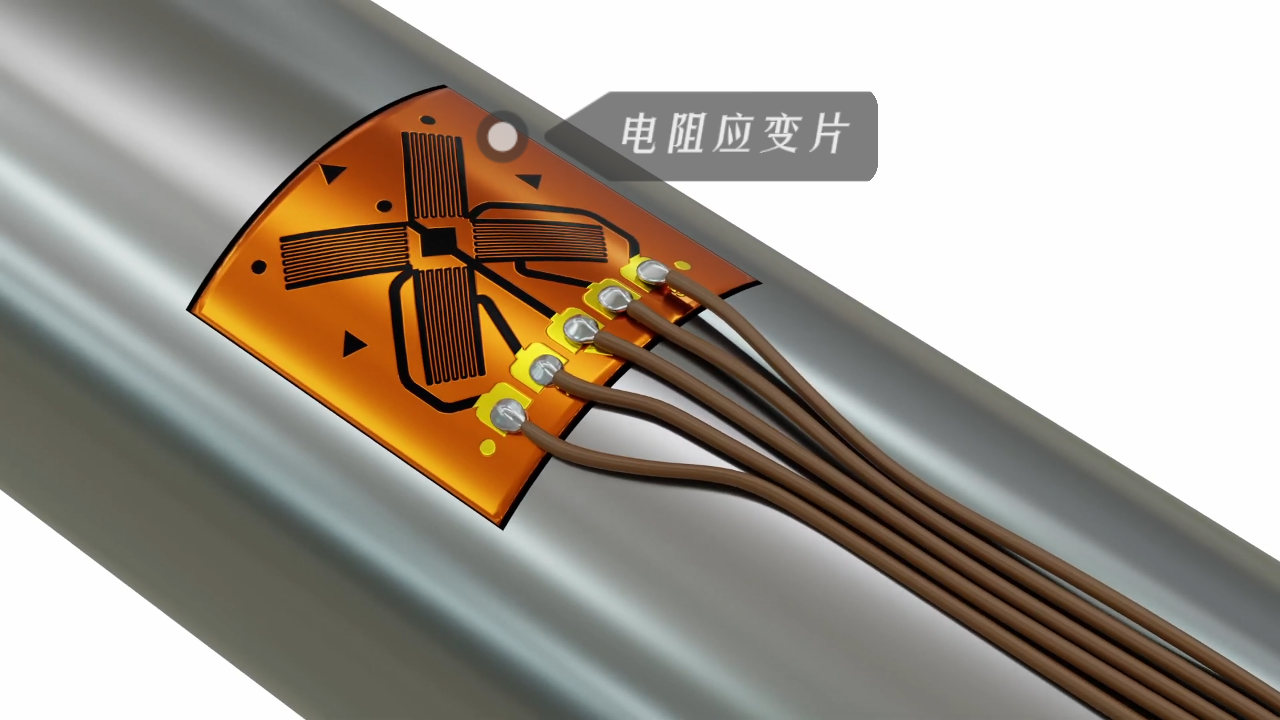

Working Principle: High-precision resistance strain gauges are usually attached to the drive shaft of the electric torque screwdriver. When the electric torque screwdriver outputs power, the drive shaft produces minute torsional elastic deformation. This deformation causes the resistance of the strain gauges to change, which is converted into microvolt-level voltage signals through a Wheatstone bridge.

Dynamic Measurement and Closed-Loop Feedback: Unlike static torque wrenches, electric torque screwdrivers perform dynamic measurements during rotation. The sensor is located at the output end of the reducer, capable of directly sensing the real torque applied to the bolt. Once the measured torque reaches the preset value, the control system immediately sends a braking command to the motor.

II. Angle Encoder: The "Eyes" of the Electric Torque screwdriver

If the torque sensor is responsible for perceiving "force," then the angle encoder is responsible for recording "displacement." In electric torque screwdrivers, angle control is crucial for identifying the "false torque" phenomenon.

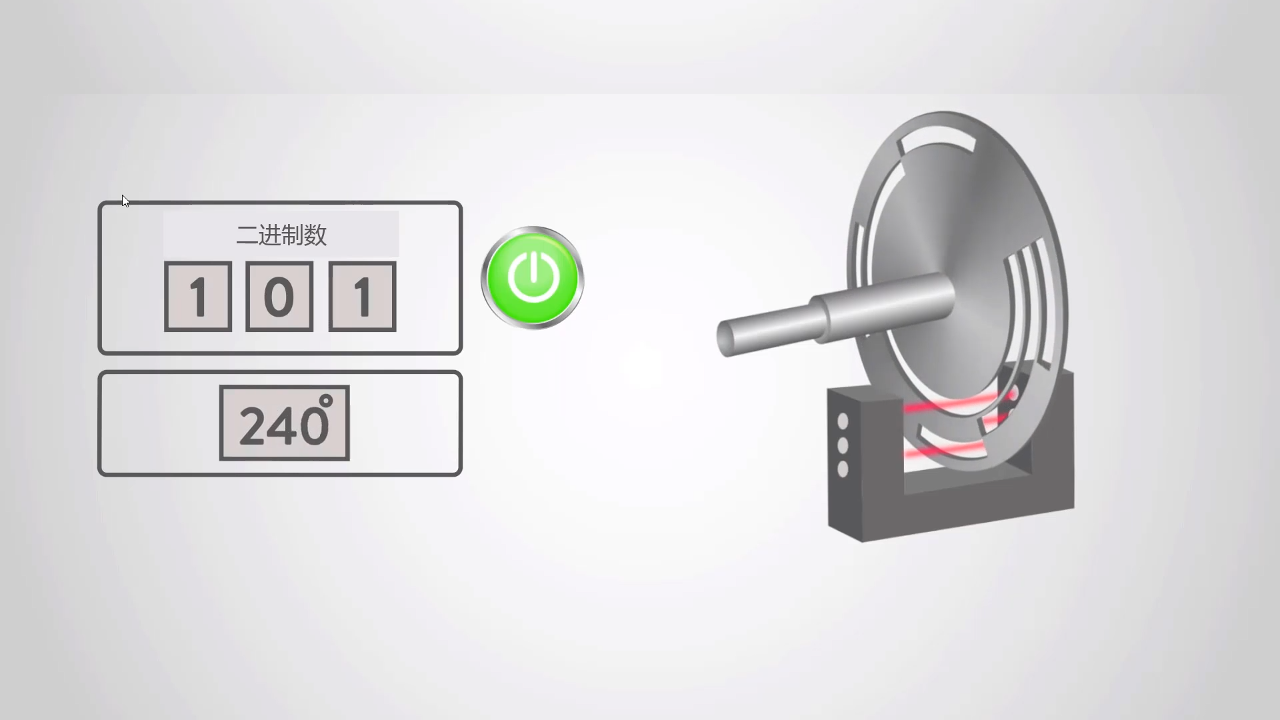

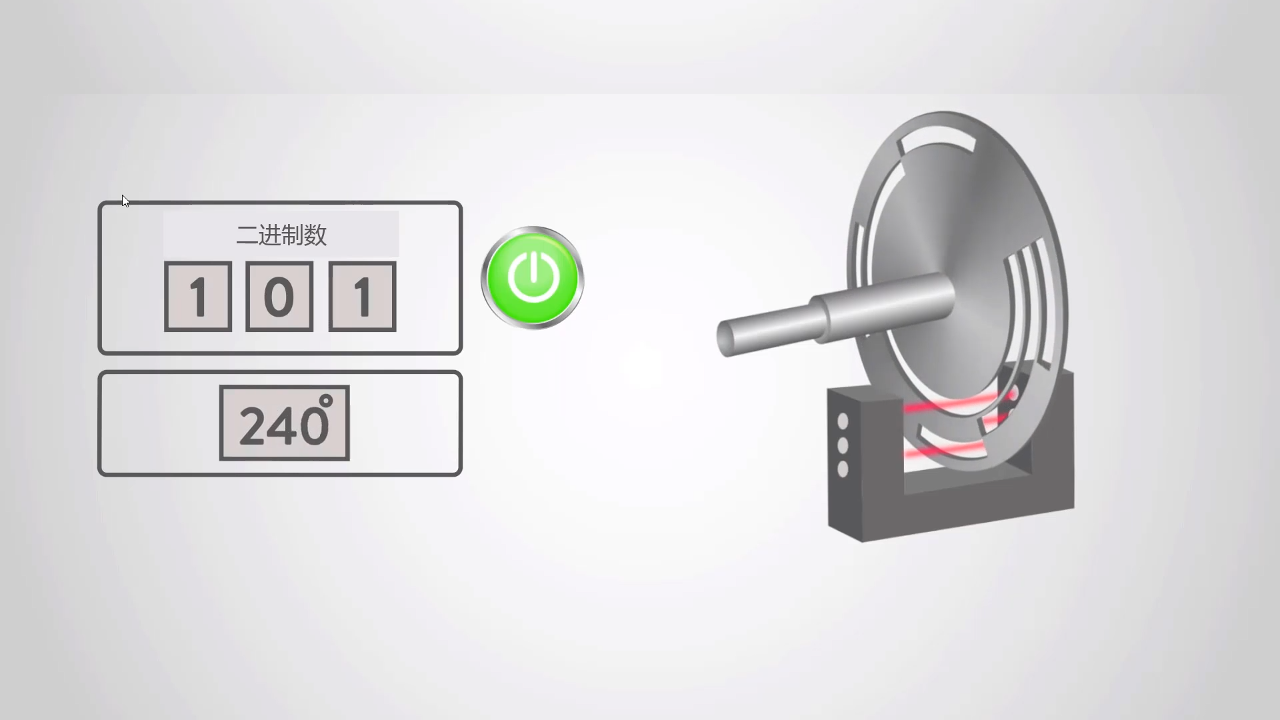

Working Principle: Electric torque screwdrivers typically use incremental encoders or magnetic encoders integrated at the rear end of the servo motor. For every rotation of the motor, the encoder generates a specific number of pulse signals. Since the electric torque screwdriver is equipped with a high-ratio reduction gearbox internally, the controller can obtain the accurate angular resolution of the output shaft by calculating the motor's rotation angle and dividing it by the reduction ratio.

Control Process: During the fastening process, the electric torque screwdriver first rotates in torque mode to the seating point, usually a small torque threshold (e.g., 10% of the final torque). Then the encoder begins counting. By monitoring the angle rotated from the seating point to the endpoint, the electric torque screwdriver can determine whether the thread is stripped or if there are foreign objects causing a "floating" condition.

Conclusion

Single torque control has its flaws. For example, if debris gets caught between threads, the electric torque screwdriver may quickly reach the preset torque, but the bolt is not actually tightened. To solve these problems, electric torque screwdrivers adopt a composite strategy of "torque control + angle monitoring" or "angle control + torque monitoring." This dual closed-loop control architecture successfully transforms the complex mechanical fastening process into quantifiable, monitorable, and programmable digital operations.