As a "barometer" of tightening quality, the tightening curve can detect whether the tightening state is abnormal in real time during the tightening process, and infer what kind of problems encountered according to the characteristics of the curve, which also plays a great role in the fault prevention management of bolt assembly.

What is the acceptable tightening curve?

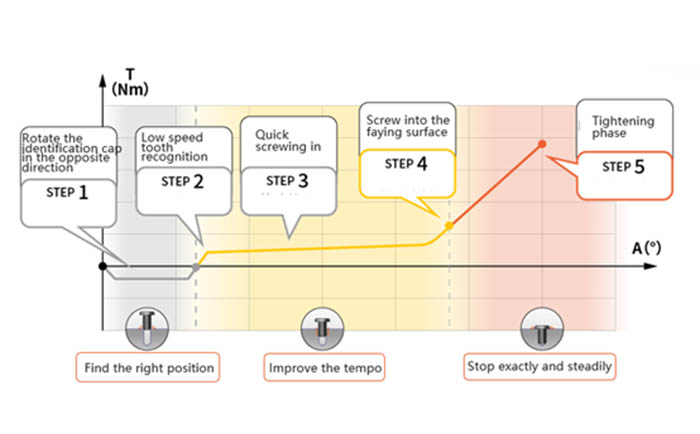

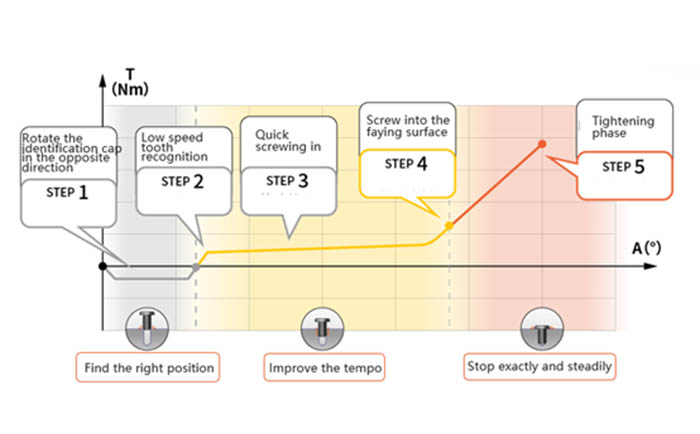

The tightening curve reflects the whole process of a screw being tightened, from reversing the cap, low speed tooth recognition, fast screwing, screwing and fitting, to the tightening stage.The torque can be monitored in real time with the changing path of screwing Angle.

At the same time, the tightening curve can more accurately reflect whether there are errors and defects in each step, and give an alarm. Therefore, it is very necessary to study the tightening curve in the error-prevention technology of the automatic assembly production line. What role can it bring?

Through the actual multi-group curve analysis, more rigorous tightening assembly process can be developed;

In the monitoring process, the potential failure can be found by fitting a large number of correct curves;

The process quantity of each tightening step can be obtained, and the error prevention can be set pertinently.

It can analyze the cause of the actual assembly failure with qualified tightening results, and trace the bad process in tightening.

According to the statistical analysis of a large number of data, the tightening curve has a relative stability. When the tightening parameters (workpiece, assembly environment, program parameters, etc.) remain unchanged, the curve of the same tightening point is basically consistent. In this regard, the measured tightening curve can be compared with the standard curve in the actual production line application. And the difference analysis can be used to determine whether the tightening is qualified and where the unqualified problem is!

In the tightening process, the tightening curve can detect the tightening anomaly in real time, which has the advantage of being more intelligent than the traditional tightening quality inspection method. The rational use of the tightening curve can provide a stronger data foundation for the subsequent tightening error prevention technology, real-time monitoring of the hidden defects, automatic identification of alarms, and quick analysis of the causes. The tightening pass rate could be improved in the tightening curve data driven action, And tightening quality is more safe, controllable and reliable!