How can AI-powered visual flexible feeding be used to distinguish automotive battery electrode sheets?

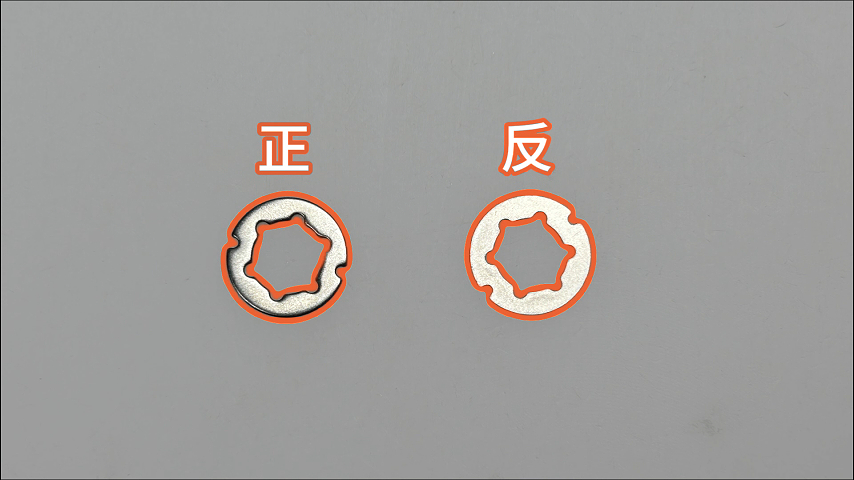

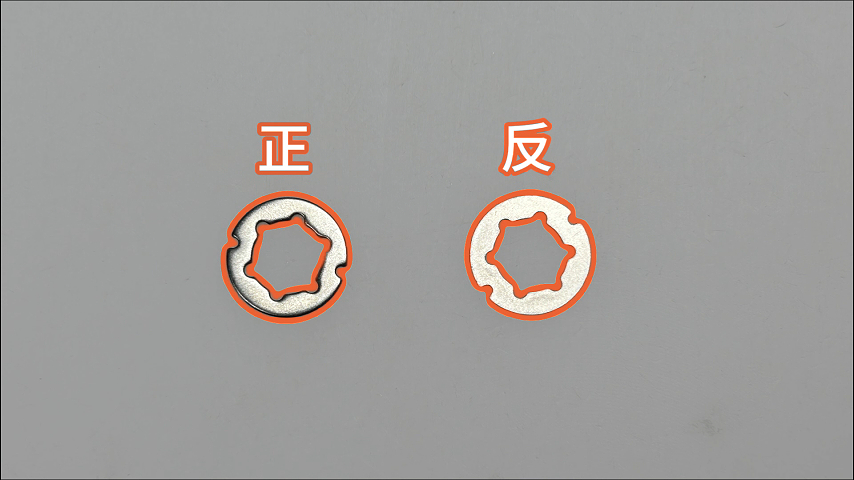

In the automated production process of automotive batteries, the precise feeding of electrode plates is a key factor that determines battery performance and service life. However, the front and back structures of automotive battery electrode plates are highly similar, posing a significant challenge in distinguishing between the two during automated feeding. Once identification errors lead to reverse installation of electrode plates, it can not only cause internal circuit confusion and a sharp decline in charging and discharging efficiency, but may also trigger safety hazards such as leakage and bulging, directly affecting the product quality and safety of the battery. Ordinary flexible vision recognition systems struggle to effectively capture the core distinguishing features between the front and back when dealing with such subtle differences, and are greatly affected by ambient lighting, increasing the error rate. Danikor improves recognition accuracy through optical optimization + AI intelligent analysis.

1. Add Upper Light Source for Uniform Illumination of Product

At the optical environment optimization level, the primary task is to build a stable and uniform image acquisition lighting environment. By using a customized upper light source system, vertical uniform light projection on the electrode plate surface can be achieved. The light uniformly covers every area of the electrode plate, effectively eliminating shadow dead corners caused by traditional point light sources or side light sources, and "visually amplifying" the originally indistinguishable structural differences between the front and back of the electrode plate, laying the foundation for accurate judgment.

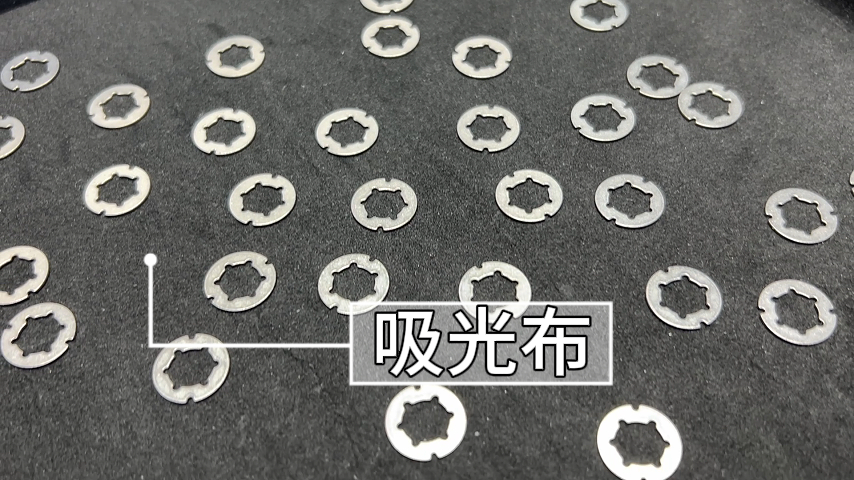

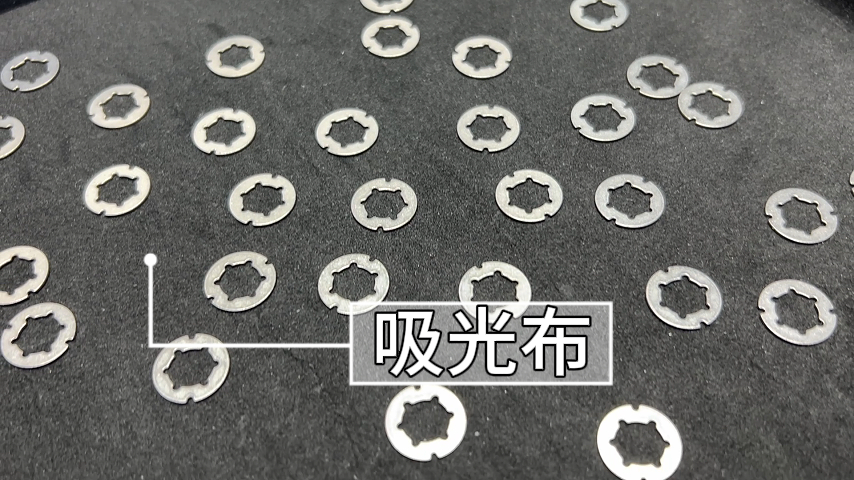

2. Apply Light-Absorbing Cloth on Tray Surface to Eliminate Stray Light Interference

Relying solely on the upper light source system cannot completely isolate external interference. Ambient stray light and bottom surface reflection are still important factors affecting image quality. Therefore, the supporting use of professional light-absorbing cloth becomes another important part of optical optimization.

On one hand, it can absorb ambient stray light in the workshop like a "black hole," including residual light from pipeline lighting, metal reflections from mechanical equipment, and light and shadow changes caused by personnel movement, preventing these stray lights from forming interfering light spots or bright spots on the electrode plate surface. On the other hand, it can completely block the reflection path from the tray bottom surface, preventing the superposition of reflected light and upper light source from causing local "overexposure" in the electrode plate image, ensuring that the brightness of the collected electrode plate image is consistent from edge to center, with complete and clear detail textures, providing high-quality image data for AI recognition.

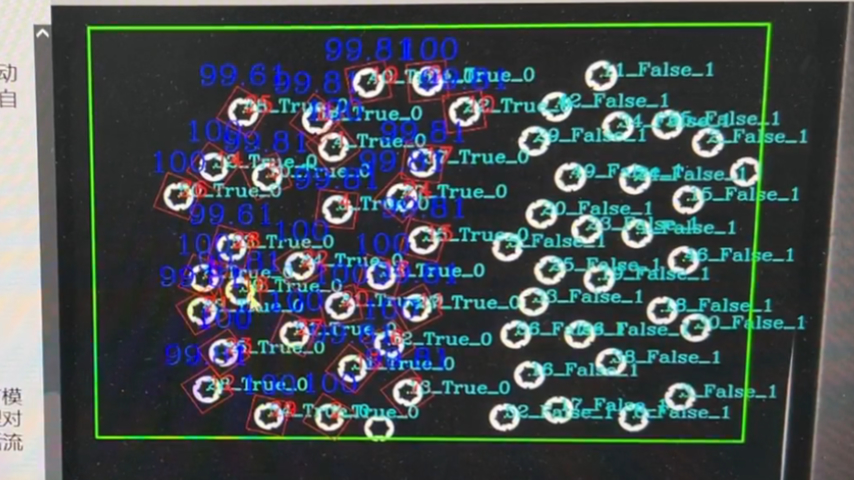

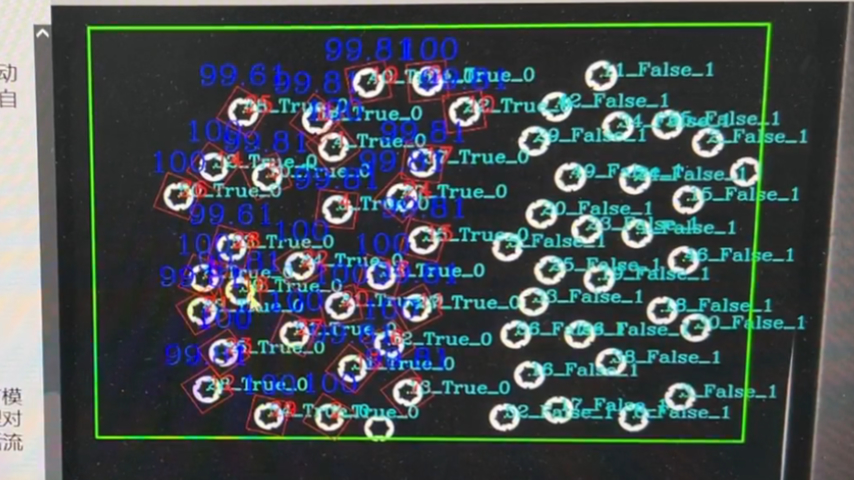

3. AI Deep Learning Samples to Improve Recognition Accuracy

At the image intelligent analysis level, based on the high-definition image data collected after optimization, deep learning algorithms are introduced to build an electrode plate feature recognition model. By collecting a large number of front and back sample images of electrode plates with industrial cameras, covering electrode plate features from different batches and positions, a rich and comprehensive sample database is constructed. Using AI to deeply train the sample data, the algorithm can automatically learn and extract the core feature points of the front and back of electrode plates at different positions and angles. Unlike traditional vision recognition that relies on manually set feature thresholds, AI algorithms can continuously optimize feature judgment logic through self-learning, thereby accurately identifying their front and back attributes.

Through the solution of optical optimization + AI intelligent analysis, the accuracy of electrode plate front and back recognition can be greatly improved, effectively eliminating production failures caused by recognition errors. This not only reduces the cost of manual re-inspection but also improves production efficiency and product quality stability, providing reliable technical support for large-scale, high-quality production of automotive batteries.