In the field of medical device production, cleanliness is the core lifeline that determines product quality and safety. The internal structure of medical devices is precise and complex, and even tiny dust particles or metal debris can cause serious hazards. Therefore, the dust-free requirements in medical device assembly are far higher than those for ordinary industrial products. As a critical process in assembly, screw locking has become one of the key technical challenges that medical device manufacturers must overcome. This article provides a detailed breakdown of how to achieve dust-free screw locking.

1. Optimize the Structure of the Screw Feeder to Reduce Contaminant Generation

The screw feeder is one of the core devices in the locking process, and its structural design directly affects the amount of contaminants produced. Traditional screw feeders often use a vibrating feeding mechanism, which sorts and conveys screws in the hopper through high-frequency vibration. This method easily produces a large amount of metal debris due to intense friction between screws and between screws and the hopper wall. To meet the high cleanliness requirements of medical device assembly, it is necessary to choose a step-type screw feeder with low contamination characteristics to reduce debris generation at the source.

The step-type screw feeder uses a cylinder to drive a push plate in reciprocating motion, allowing screws to rise steadily step by step without violent vibration or friction, fundamentally reducing the probability of metal debris generation. Additionally, the bottom of the hopper is designed with holes and paired with a customized vacuum adsorption component to form a continuous negative pressure environment, which can real-time absorb dust and fine debris in the hopper, achieving preliminary cleaning of the screws.

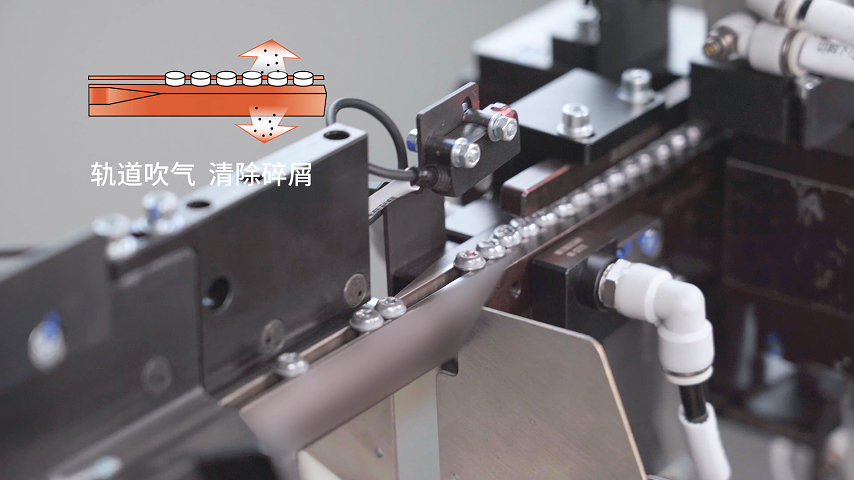

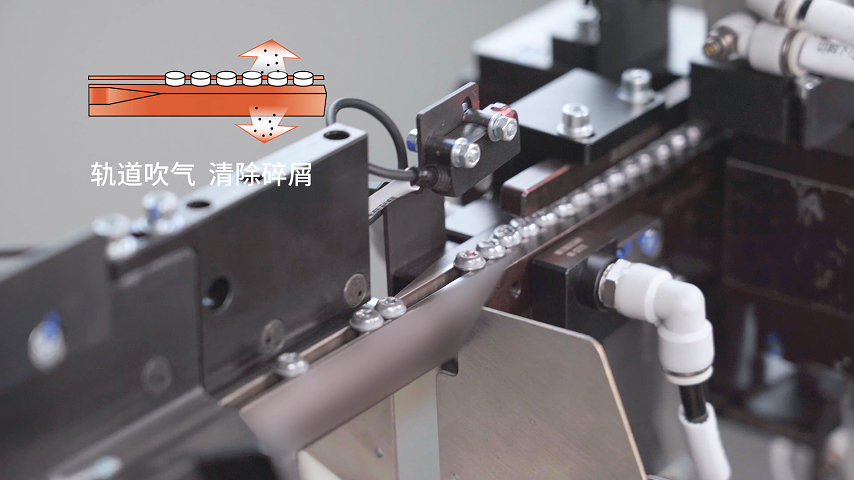

2. Configure Track Cleaning Components to Enhance Mid-Process Purification

As screws are conveyed along the straight vibration track to the cutting mechanism, dedicated cleaning components can be added on both sides of the track. These components use directional air-blowing cleaning technology to spray clean airflow onto the screw surface and thread gaps with controllable air pressure (which can be adjusted according to screw specifications and impurity types), achieving secondary deep purification. This not only efficiently removes dust, oil stains, metal debris, and other micron-level impurities attached to screws during storage and transportation, but also avoids scratches or posture shifts that may be caused by traditional cleaning methods. The design of the cleaning components fully adapts to the conveying rhythm of the straight vibration track, ensuring cleaning without affecting the stability of screw conveying.

3. Add External Cleaning Modules to Achieve Deep Dust Removal

After the air-blowing cleaning of the feeding track, there may still be some fine dust particles or strongly adsorbed debris remaining on the screw surface, especially in hidden parts such as thread gaps and small holes in the screw head, which are difficult to thoroughly clean with ordinary air-blowing. To address this issue, an external cleaning module can be added between the screw feeder and the locking nozzle to achieve deep purification through vacuum dust removal technology. The module adopts a closed structure design. When the screw is conveyed to the cleaning module, the high-intensity vacuum suction can extract residual impurities from the gaps.

The vacuum system of the external cleaning module needs to be equipped with an efficient filtration device. The collected contaminants will be intercepted by the filter device to prevent them from entering the vacuum pump and causing equipment damage, while also preventing contaminants from flowing back into the cleaning area.

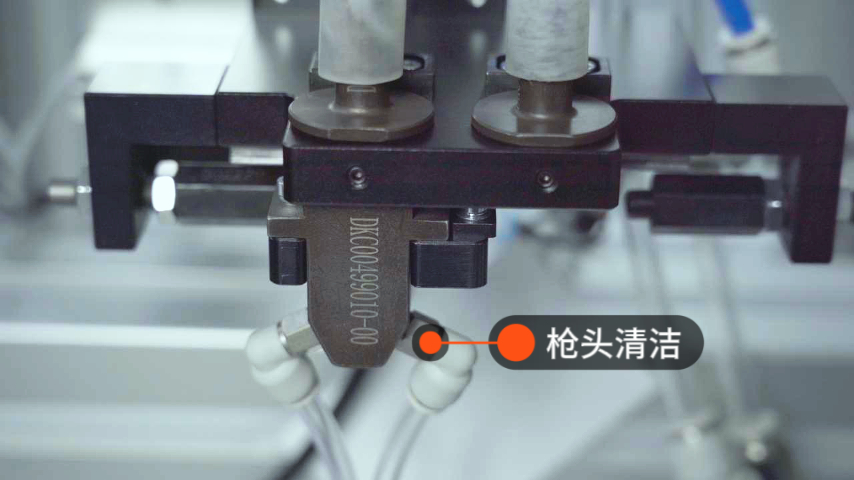

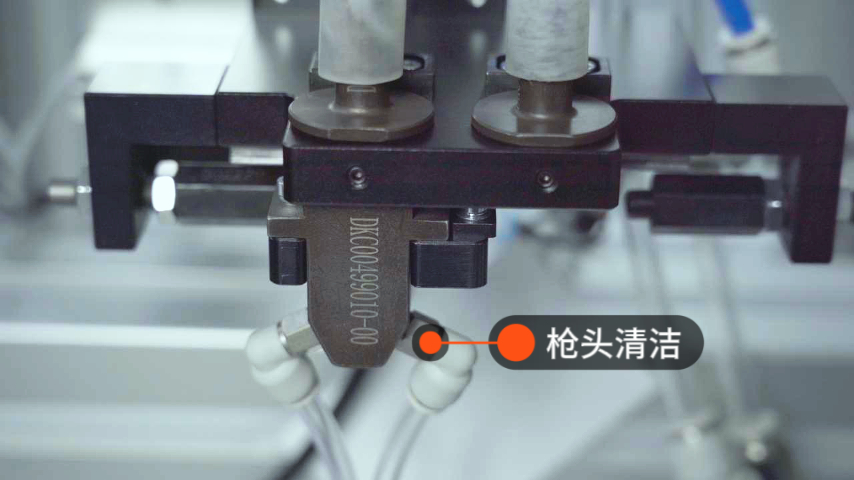

4. Install Nozzle Vacuum Components to Eliminate On-Site Contamination

Although the external cleaning module has achieved deep dust removal on the screw surface, in actual production scenarios, there are still two major potential impurity risks: First, hidden parts such as micropores and thread grooves on the screw surface may still have micron-level dust, oil stains, and other attachments, which are difficult to completely penetrate with conventional cleaning; Second, when the screw is quickly conveyed to the nozzle by high-pressure airflow, instantaneous collisions with the clamping block and guide channel may generate tiny metal debris. If these debris enter the locked workpiece along with the screw, they may also affect the precision of the medical device.

To avoid the above risks and further improve the stability and reliability of the locking process, a customized vacuum cleaning component can be installed at the locking nozzle. This component uses the principle of negative pressure adsorption to form a local high vacuum environment before the screw enters the locking process, thoroughly removing screw impurities.

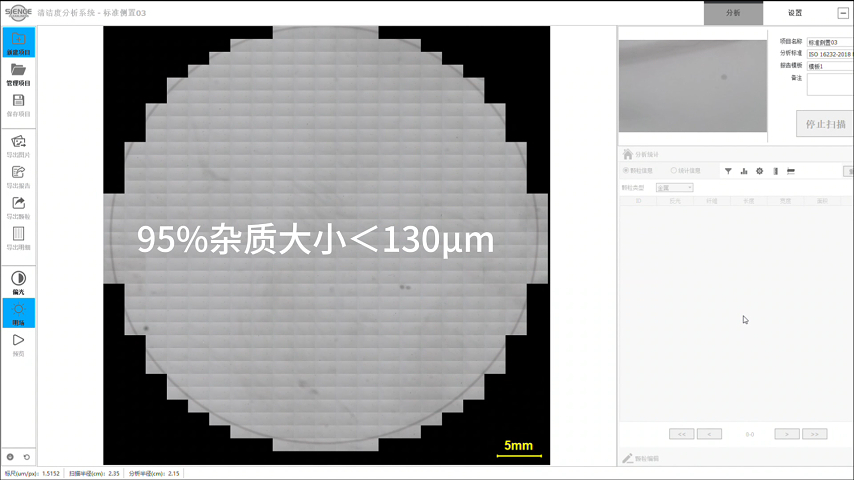

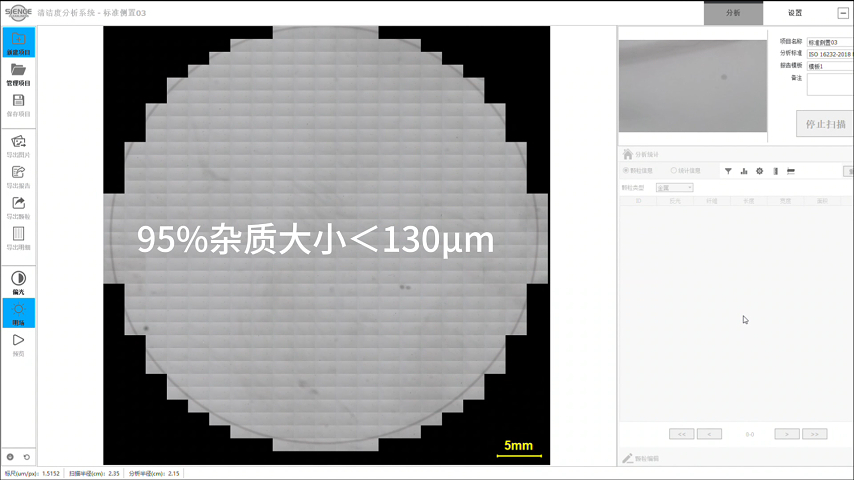

5. Cleanliness Detection and Data Support

Through the above multiple cleaning processes, the cleanliness of screws and the locking site can be effectively improved. According to actual testing data, this solution can achieve a cleaning efficiency of over 95% for dust particles larger than 130μm, fully meeting the strict cleanliness requirements of medical device assembly.

In the actual production process, it is necessary to regularly test and verify the cleaning effect of the dust-free locking system to ensure stable equipment operation. At the same time, a comprehensive equipment maintenance system needs to be established, regularly cleaning vacuum components, replacing filter devices, and checking the operating status of cleaning components to ensure that all equipment is always in the best working condition.